Biofeed System Configurations & Options

Bin Loading Options

- Manual Loading – Standard for small bins

- Gas-Strut Assisted Loading – For Slim Jim-style bins

- Electric Bin Lifters – For 80L, 120L, and 240L bins

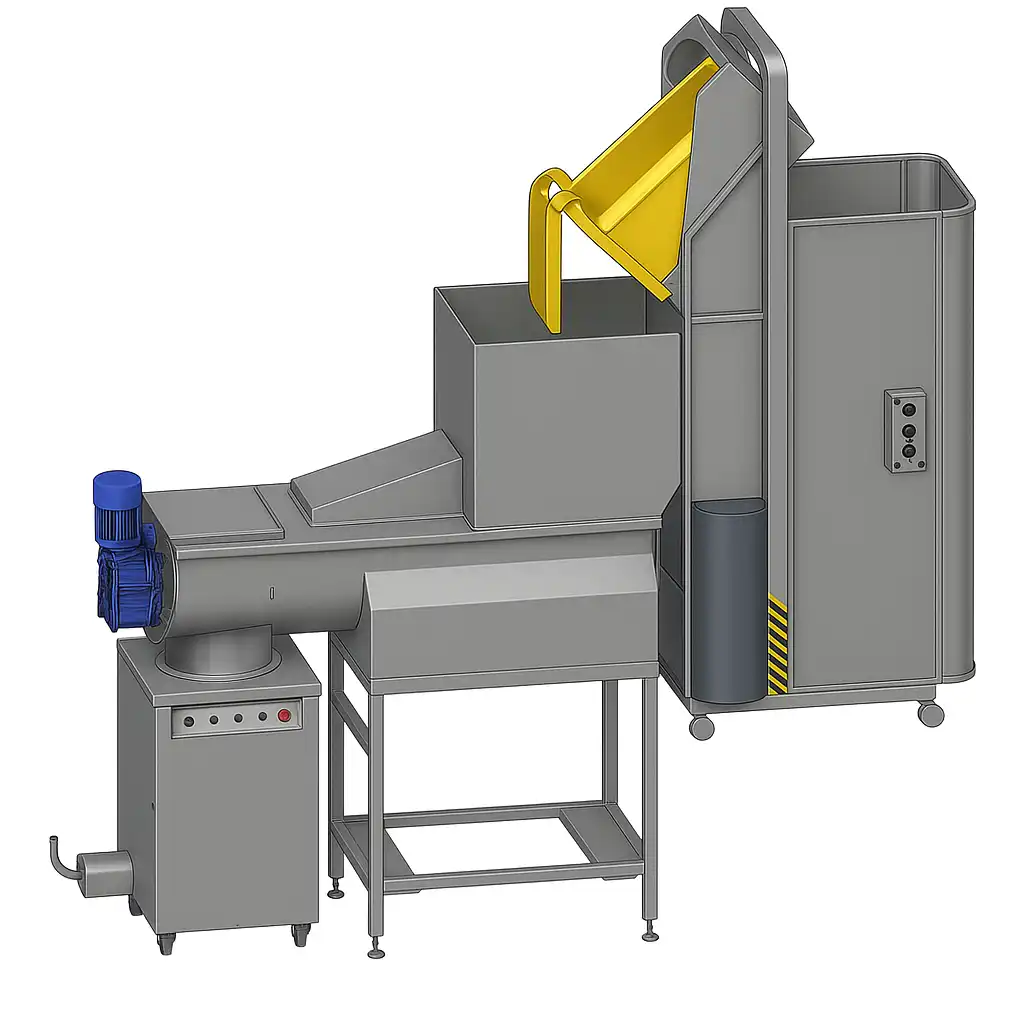

- High-Throughput Auger System – Load multiple bins quickly without operator attendance

Data & Technology Options

- Live Cloud-Based Dashboard – Real-time visibility of food waste volumes

- Automated Tank Level Alerts – Notifications at 75% and 90% capacity to prompt pump-out

- Remote Diagnostics Access – Enable off-site service support and monitoring

- FOB Access Control (Optional) – Track usage by tenant or department for reporting and cost allocation

Tank Sizes & Dimensions

- 1000L Slimline – H: 2020mm | L: 1320mm | W: 790mm

- 2000L Slimline – H: 2020mm | L: 1970mm | W: 790mm

- 3000L Slimline – H: 2020mm | L: 2515mm | W: 870mm

- 4000L Slimline – H: 2020mm | L: 2880mm | W: 1040mm

- 5000L Slimline – H: 2020mm | L: 3320mm | W: 1040mm

Custom Options Available

- Larger tanks available upon request

- Liquid separator tanks for long plumbing runs or high-solids content

- Integration with existing grease separators (site inspection required)

- Customised solutions for multi-tenant or shared-use infrastructure

Typical Standard Configuration

Typical for a Hospitality Venue

For larger food waste producers – such as shopping centres or high-volume hospitality sites – we recommend:

- Electric bin lifter integration for efficient tipping of 120L or 240L bins

- *Optional auger feed system to handle multiple bin loads in succession with minimal operator input